4.8 / 5.0

(10) 10 total reviews

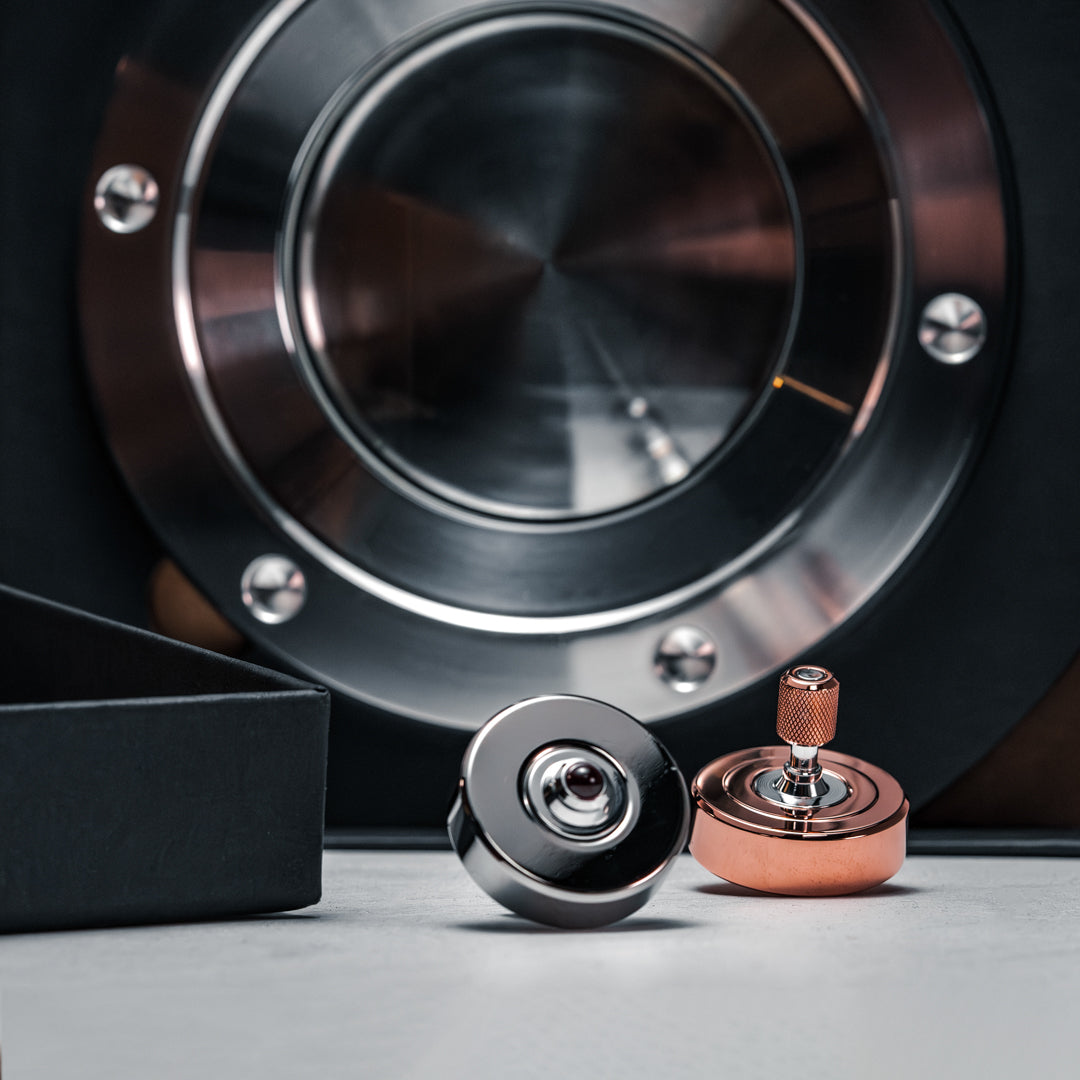

Polished Black Chrome Mk1

Polished Black Chrome Mk1

Free Shipping

Couldn't load pickup availability

Polished Black Spinning Top MK1

What is Black Chrome?

Black Chrome is a coating commonly used on high end cars, emblems and firearms. Firstly coated with protective nickel and then followed by a smoothing, more reflective layer of dark chromium. Although the coating is very thin, usually only a few microns, due to the strength of the coating it can last for many years and can also reduce scratches and damage to a highly polished surface, meaning the polish will stay looking sharp for years to come.

The base material for our Black Chrome products is brass.

About the Mk1 spinning top:

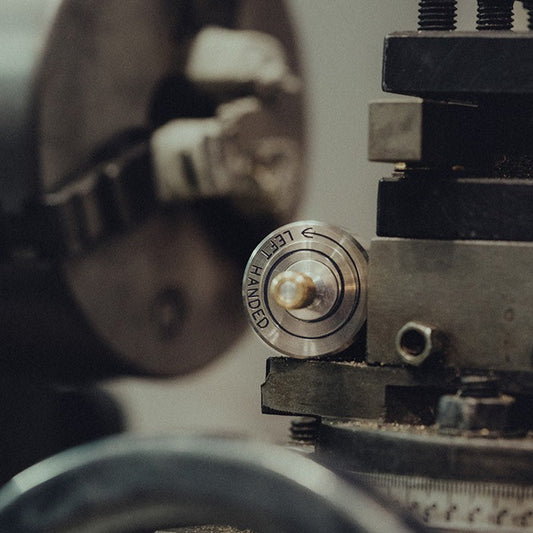

Each piece is precision machined on state of the art CNC lathes, producing perfectly balanced components. Once machined, each section is meticulously quality checked for weight and dimension. As well as making sure every millimetre is of the correct surface standard, they are then, and only then, hand finished and assembled in our workshop in Staffordshire, England.

It’s also an evolved version of the top which launched our successful Kickstarter campaign which means it has a tonne of Vorso history behind it.

With an improved knurled texture to the top of the spindle gives better grip, which in turn (pun intended) allows much more torque to be put into each spin, meaning more speed and longer times.

Mk1 Materials

-

Mk1 Spinning Top - Brass

Regular price From £52.00 GBPRegular priceUnit price / per£42.00 GBPSale price From £52.00 GBP -

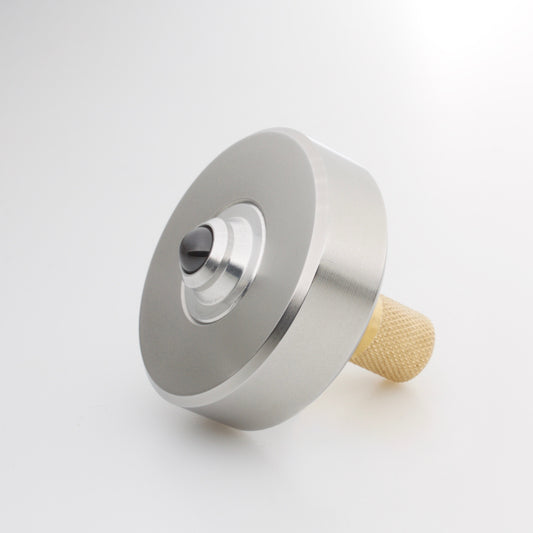

Mk1 Spinning Top - Stainless

Regular price From £52.00 GBPRegular priceUnit price / per£50.00 GBPSale price From £52.00 GBP -

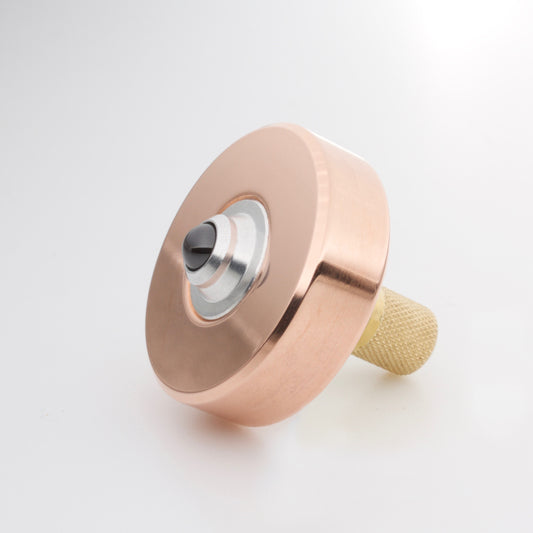

Mk1 Spinning Top - Copper

Regular price From £52.00 GBPRegular priceUnit price / per£54.00 GBPSale price From £52.00 GBPSale -

Polished Black Chrome Mk1

Regular price From £100.00 GBPRegular priceUnit price / per£80.00 GBPSale price From £100.00 GBP -

Mk1 Spinning Top - All Brass

Regular price From £68.00 GBPRegular priceUnit price / per£54.00 GBPSale price From £68.00 GBP -

Custom Engraved Mk1 Spinning Top

Regular price From £78.00 GBPRegular priceUnit price / per -

Build-a-MK1

Regular price £120.00 GBPRegular priceUnit price / per -

World's First Left Handed Spinning Top

Regular price From £68.00 GBPRegular priceUnit price / per -

Sold out

Sold outMk1 JBE Limited Special

Regular price £120.00 GBPRegular priceUnit price / per

Your questions, answered.

What's the best choice for me?

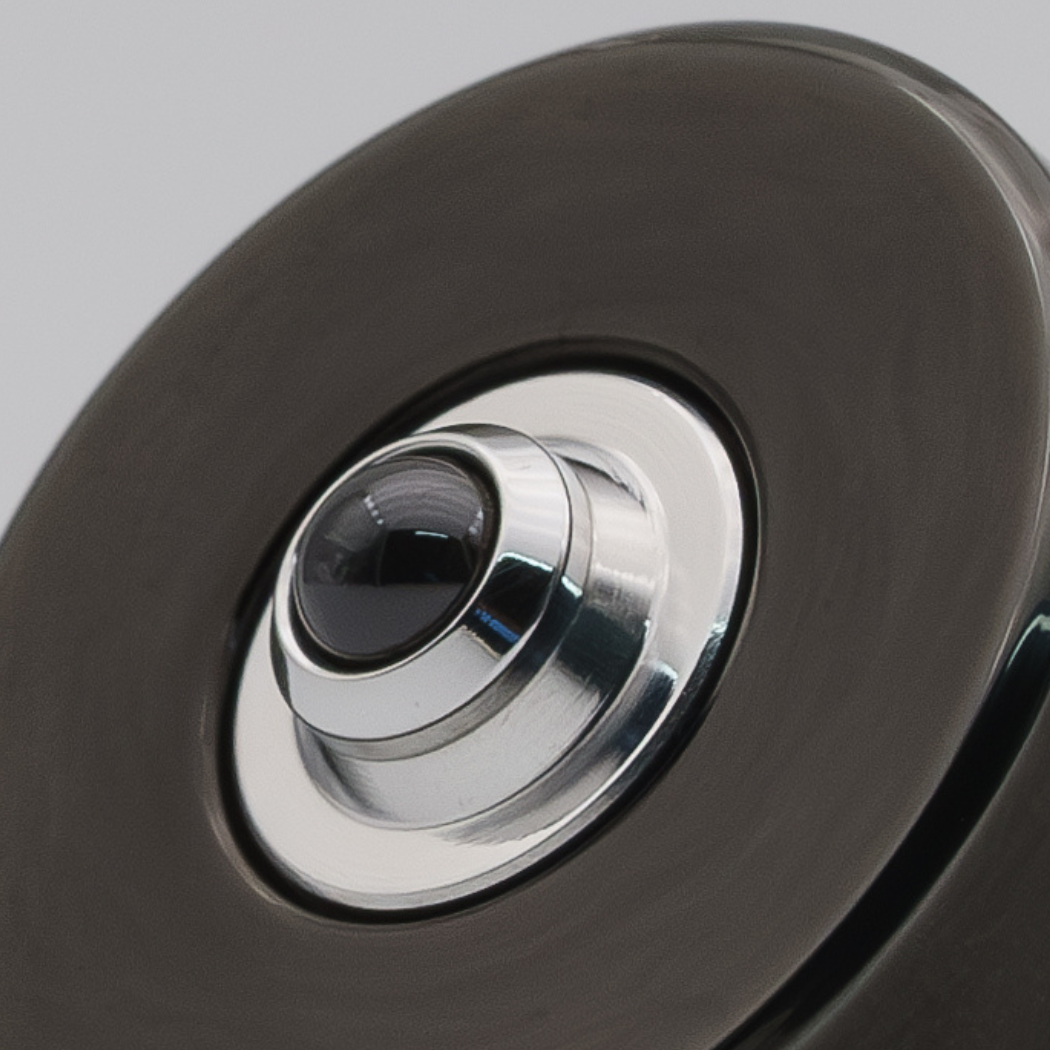

Ceramic vs Ruby

Ceramic: Made from ultra-durable silicon nitride, ceramic bearings score 7 out of 10 on the Mohs hardness scale. Nearly impossible to dent, they’re used in high-performance applications like rocket engines and bulletproof vests.

Ruby: For those who value both luxury and performance, ruby bearings offer a superior upgrade. With a near-perfect spherical shape and a hardness of 9 on the Mohs scale, they reduce surface friction for longer spin times and greater longevity. Ruby also adds elegance, often found in precision tools and luxury watches.

Machine Finished vs Polished

This choice ultimately comes down to personal preference.

Machine Finished

Every line and detail is beautifully rendered in the machine finish, showcasing the precision of the machining process. The final touch adds a subtle brightness, making it perfect for purists who appreciate the intricate details of expertly engineered pieces.

Polished

The mirror polish is ideal for those who love a blend of simplicity and elegance in design. While it doesn’t enhance spin times, it adds a sense of beauty as it reflects surrounding colors and light. Perfectly complemented by a ruby contact point, our polishing process has been refined to meet, and possibly exceed, the standards of the jewelry industry.

For the engineering enthusiasts: The machine finish is technically more precise since hand polishing microscopically removes material, altering the metal until it’s nearly smooth. This precision means the machine finish is slightly more balanced, slightly heavier, and could theoretically result in slightly longer spin times—though our tests have yet to show a consistent difference.

Which metal?

Brass strikes the perfect balance—heavier than stainless but not as weighty as copper. It provides long, steady spins.

Stainless steel is the most durable and can withstand more abuse, though it's the lightest of the three. Despite this, its spin times can easily exceed 8 minutes, and the polished finish resembles liquid metal when it spins.

Copper, being the heaviest, offers slightly longer spin times and warms quickly in your hand, providing a fantastic feel and appearance.

Note: Patina; Stainless steel stays pristine, while brass and copper develop a subtle patina. A quick clean restores their shine, and our alloys won’t cause any odors.

Ship it, ship it baby

Shipping & Taxes

How much is shipping and do you ship to my country?

Free shipping is available on all orders.We ship to all countries in the world, and we have both free regular shipping andexpress shipping via UPS or FedEx at reasonable prices.

How long will it take to arrive?

Orders are normally shipped within one working day, however, your location in the world will change the delivery time.

- USA - up to 12 days

- EU - up to 6 days

- UK - up to 2 days

- Asia Pacific - up to 12 days

- Rest of the world - up to 14 days

Are taxes included?

Yes, Value-added taxes are included in the price you see above. Please contact us if you require specific tax information.

Vorso Guarantee

We stand by our products and live by our quality, and as such we offer a lifetime guarantee to repair or replace any of our products in the future, indefinitely. I’m proud to say that out of the thousands of Mk1s that have been made only a handful have ever needed repairs or replacement. Contact points are also included in our guarantee, which can easily be replaced at any time if required. Complimentary surface restoration and deep clean is also included at your request.

learn more.

Spin times

Which top has the best spin times?

Currently, the Tom has the best spin times, closely followed by the Mk1. The Sunny and the Dervish have nearly identical spin times, with the Stanley coming in just after them.

Which material has the best spin times?

In our production models, copper typically delivers the best spin times due to its heavier nature, providing just a bit more oomph. Brass ranks second, with stainless steel coming in third, though the difference between brass and stainless is often minimal. For the longest spin times we offer, check out our custom Tungsten Mk1.

Which top is easiest to spin?

While this can vary depending on the user, the Stanley is likely the easiest to use, followed by the Mk1 and Sunny. The Tom and Dervish come next in terms of ease of launch.

Average spin times.

Spin time will vary based on your technique, as outlined below:

Virgin – 2-3 minutes

Newbie – 4-7 minutes

Solid Gripper – 7-10 minutes

Hard Hitter – 10-14 minutes

Spinning Tops

-

Mk1 Spinning Top

The Mk1 is a British-made performance spinning top made for those with...

-

Sunny Special Mk1

An exciting design built on the Mk1 profile.

-

Whirling Dervish

Designed in 2017 the Whirling Dervish was our first top made fully...

-

Tom Spinning Top

Introducing the Tom A blend of function and artistry with a slim...

Heavy

Weights & Dimensions

Mk1

Stands at 31mm // 1.22 Inch tall

Sits at 28mm // 1.1 Inch diameter

Bearing diameter: 0.2 in (4.7 mm)

Weight:

Brass: 42.5g // 1.50 Oz

Stainless: 41g // 1.45 Oz

Copper: 44g // 1.55 Oz

Sunny

Stands at 31mm // 1.22 Inch tall

Sits at 28mm // 1.1 Inch diameter

Bearing diameter: 0.2 in (4.7 mm)

Weight:

Brass: 37.0g // 1.30 Oz

Stainless: 34.6g // 1.22 Oz

Copper: 39.0g // 1.38 Oz

Dervish

Stands at 31mm // 1.22 Inch tall

Sits at 28mm // 1.1 Inch diameter

Bearing diameter: 0.2 in (4.7 mm)

Weight:

Brass: 48.7g // 1.72 Oz

Stainless: 45.6g // 1.61 Oz

Copper: 52.5g // 1.85 Oz

Stanley

35mm tall by 18mm at the widest diameter.

Tom

28mm diameter // 41mm tall

Beginner's sets & Bundles.

Not sure where to begin, or looking to kickstart your collection? Explore our bundles for the best prices.

Vorso

The Beginner's Set

Share

Why Vorso spinning tops?

Spinning tops have been mesmerizing humanity for over 5,500 years, like watching a fire, they are incredibly satisfying- even addictive. Spinning tops have emerged in cultures all over the globe, from ancient Japanese fighting tops to African whip tops, but at Vorso we offer something very much made in modern times. Our spinning tops are created using computer-aided design and simulation, machined on modern CNC lathes, and manufactured in aerospace level materials.